I-SMS ye-PP ye-Spunbond ye-Meltblown edityanisiweyo yeLaphu engenziweyo yokwenza iMveliso yoLungiso loMatshini kwizicwili ezimanzi

Ukunikezelwa kwemveliso

I-SMS yemveliso engavelwanga

Amalaphu eSMS asetyenziswa ngokubanzi kumacandelo ahlukeneyo, afana nonyango, izinto zangasese, ukhathalelo lwempilo, S okanye amalaphu e-SS anokusetyenziswa kwizigqubuthelo zobuso, ezolimo, ulwakhiwo, ukupakisha, amalaphu asekhaya, njl.

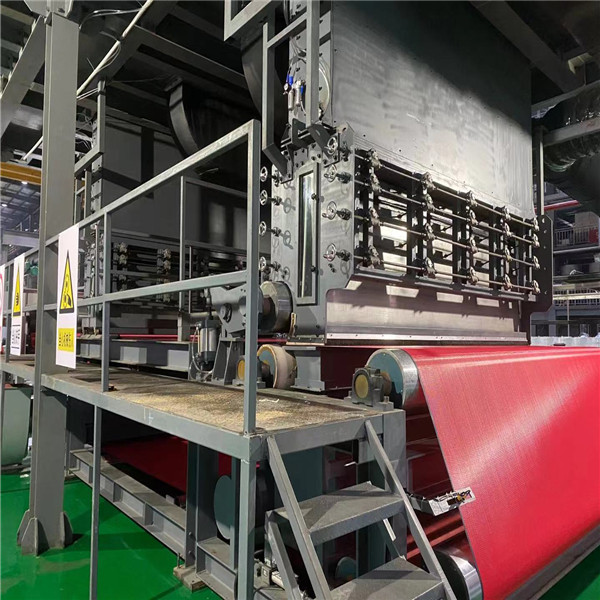

Umgca wemveliso ye-polypropylene spunbond nonwoven

I-polypropylene spunbonded non-ephothiweyo umgca wemveliso yelaphu eveliswe yinkampani yethu iye yamkelwa ngokubanzi ngabavelisi belaphu abangaziwayo abangaluki kwilizwe lam, kwaye bathunyelwa eYurophu, eAsia, eAfrika naseMelika.

Ukusetyenziswa kwendalo

Lo matshini ulungele ukuveliswa kwe-polypropylene fiber ejijelwe kumnatha, eshushu-esongiweyo kunye ne-non-ephothiweyo yelaphu, kwaye iimveliso zayo zinokusetyenziswa kwezonyango nakwezempilo, ulwakhiwo, i-geotechnical, ezolimo kunye namanye amashishini kunye nezinto zekhaya

Iiparamitha eziphambili zobugcisa

Ifom yemveliso: S, SS, SSS, SMS, SMMS, SSMMS

Ububanzi: 1600, 2400, 3200 (mm)

Ubungakanani besponbond monofilament: 1.5dte ~ 2.5dtex

Ubungakanani beMeltblown monofilament: 1.0 ~ 2.0η

Ubunzima bencwadi obugqityiweyo: S 10g ~ 150g / ㎡

I-SS 10g ~ 70g / ㎡

I-SSS 11g ~ 70g / ㎡

I-SMS 10g ~ 70g / /

I-SMMS 12g ~ 70g / ㎡

I-SSMMS 15g ~ 70g /

Isantya esiphezulu soomatshini: S 150m / min

SS 350m / min

I-SSS 450m / min

I-SMS 450m / min

I-SMMS 450m / min

I-SSMMS 450m / min

| INTO | Ububanzi obusebenzayo | I-GSM | ISIPHUMO SONYAKA | UMZEKELO WOKUGQIBELA |

| S | 1600MM | 8-200 | 1500T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| S | 2400MM | 8-200 | 2400T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| S | 3200MM | 8-200 | 3000T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| SS | 1600MM | 10-200 | 2500T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| SS | 2400MM | 10-200 | 3300T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| SS | 3200MM | 10-200 | 5000T | Idayimani, okweqanda, umnqamlezo kunye nomgca |

| i-SMS | 1600MM | 15-200 | 2750T | Idayimani kunye ne-oval |

| i-SMS | 2400MM | 15-200 | 3630T | Idayimani kunye ne-oval |

| i-SMS | 3200MM | 15-200 | 5500T | Idayimani kunye ne-oval |

Iinkcukacha imveliso nonwoven

Iimpawu zalo matshini

1. Isixhobo sokutsala, isixhobo somlinganiso kunye nokuxuba samkela ulawulo lwenguqu rhoqo, oluchanekileyo noluthembekileyo; inqanaba lezinto ezibonakalayo lidlula umda kwaye ngokuzenzekelayo ii-alamu.

2. Isikulufa extruder samkela isikhululo se-helical ephezulu ngokuthe ngqo. Umbane wamkela ulawulo lwe-loop evaliweyo, ukuze i-extruder ibe neempawu zokuchaneka okuphezulu, ukuthembeka okuphezulu, ukusebenza okuphezulu kokhuseleko kunye nobomi benkonzo ende.

3. Umbhobho onyibilikayo wamkela ifom yokufudumeza yombane, kunye nezinto zokugcina ubushushu zingaphandle, ezineempawu zokuhamba okunyibilikayo okufutshane kunye nolawulo oluzenzekelayo lokufudumeza nolondolozo lobushushu.

4. Ukufa okusontayo kukwenziwe uqhekeko ngokubanzi, kwaye kunyanzeliswa indawo yokuhambisa inyibilika ekhethekileyo, ukuze inyibilike isasazwe ngokulinganayo. Ipleyiti yokutshiza iyonke isetyenziselwa ukwenza ukuhanjiswa kokuhanjiswa ngokulinganayo.

5. Icala lokuvuthela lamkela ulwakhiwo olunamacala amabini alinganayo, kunye nezixhobo ezininzi ezilungisa umaleko ezifakwe kumbhobho womoya.

6. Uyilo lwentambo yomoya yamkela uhlobo olusikiweyo lokuyila urhuqo ngokuhamba komoya. Idrafti yomoya eyilwayo esezantsi, idisk yomoya osasazwayo, ububanzi bayo buhlengahlengiswayo.

7. Umatshini wokufaka umnatha ubunjwe yidrive ephambili, ikhethini yomnatha, isakhelo, isixhobo sokutsala, isixhobo sokulungisa, isixhobo sokuqinisa kunye nezinye iindawo.

8. Ukutsalwa kunye nokusasazwa kwemijelo yomoya yahlulwe kwindalo esingqongileyo phantsi kwentshukumo yeebrashi kunye nokutywina iiroller, zenza ulawulo olwahlukileyo ukuhlangabezana neemfuno zenkqubo ezahlukeneyo.

9. Ulawulo oluzenzekelayo oluphambili. Umgca wemveliso uphela usebenzisa ikhompyuter yokujonga kunye nokulawula yonke inkqubo yetekhnoloji. Sebenzisa i-PLC ukulawula umgca wemveliso yonke. Inkqubo yebhasi ye-Profibus isetyenziselwa ukunxibelelana nabaguquli bamaxesha ohlukeneyo kumgca wokuvelisa onje nge-screw extruder, umatshini ojikelezayo, umatshini wokunatha, ishushu sokugaya eshushu, i-winder, njl njl, nokunxibelelana nemodyuli yokulawula ubushushu bomgca wemveliso ngokusebenzisa ibhodi yonxibelelwano.

10. Ingabonisa umzobo weskimu wenkqubo yezixhobo, iiparameter eziphambili zenkqubo (ubushushu be-screw, ukunyibilika kobushushu kumbhobho, ubushushu bendawo yokufa, isantya sempompo yokulinganisa, isantya somatshini wokuhambisa, isantya sokugaya eshushu, inkqubo yeeparamitha zesixhobo sokupholisa umoya esisetyenziswe Inkqubo ye-spunbond, ukunyibilika Ixabiso lokumisela kunye nexabiso lokulinganisa kwezixhobo zomoya oshushu ezisetyenziswa kwinkqubo yokujikeleza kwejet, ezinje ngeeparamitha zenkqubo yokujikeleza, kunye nexabiso lealam kwindawo nganye yokulawula.Ingabonisa itshathi yeencwadi zembali yobugcisa, kwaye unokuprinta idatha yembali yobugcisa.

11. I-polypropylene spunbond engalukanga umgca wemveliso yelaphu yamkela ubuchwephesha bokufa obunye kunye nenkqubo yokupholisa ukuthengisa kunye nokuvuthela inkqubo, kudityaniswe netekhnoloji yokuyila umoya kunye nobuchwephesha bokwenza ubuchwephesha bewebhu, kunye nenkqubo yolawulo lwedijithali, ukuze ukufana kwemveliso ilungile, Inezinto ezinobungakanani bobungakanani obucolekileyo, amandla aphezulu athe nkqo kunye athe tyaba, kunye nokusetyenziswa kwamandla okuphantsi. Ukusebenza ngokubanzi komgca wemveliso kuye kwafikelela kwinqanaba eliphezulu lobugcisa bezixhobo ezifanayo zangaphandle